Electric Cars – Bain or Boom?

Despite what we’re often told, today’s re-emergence of the electric powered car is not all roses. Yes, battery technology is better than 1900, but not as much as one might think. Certainly, there will be more progress. But for the foreseeable future (thanks primarily to government edict), what does an automobile market potentially dominated by electric vehicles look like?

In the beginning, steam, electricity and gasoline vied for dominance in the automobile industry. For a brief time, electric cars actually dominated because they were the easiest to use and, therefore, the most practical. Gasoline eventually won out because internal combustion engines could go longer distances without refueling. Combined with the oil industry’s might to provide supporting infrastructure it eventually became no contest. By the time the steam condenser made its way to cars the internal combustion engine had already secured the market.

European governments are being particularly aggressive in pushing electric and hybrid cars. Many of them have already set bans on the sale of internal combustion engined vehicles – Norway by 2025, Germany by 2030, France and Great Britain by 2040. The Chinese already buy over a million electric cars a year.

Many people see electric powered vehicles as the solution to our global warming and pollution issues. It is, however, a simplistic and misguided view that does not take into account the costs, both economic and environmental, to getting there. It’s my opinion most people have no clue and give no thought to how electricity and batteries are produced. The idea that electricity comes from the wall socket and is something we produce easily and prodigiously is far from reality. Plugging my car into the electrical outlet every night seems cleaner than the gas station, and at that point it is. But electricity derived from the original energy sources is far from that simple or clean. What does it take to get to the outlet, and what does it take to make the batteries that store the electric energy?

Some say we will have a clean, renewable electric energy grid in a few years. Right now, the US gets just 18% of its electrical grid energy from renewable sources such as wind, solar and hydroelectric. But the use of electric vehicles is predicted to increase grid demand as much as 38% by 2050. Then there’s the question of where we will store all that solar and wind energy that can’t be immediately fed to varying grid demands. The current answer is huge battery farms covering millions of square feet of warehouse space in remote areas. Who will pay for all that new infrastructure? We already are to some extent, and with the aggressive push to electric cars it seems it will only get more expensive.

Let’s start with the idea of energy conversion & conservation. Converting raw materials into useable energy takes energy; we must use machines powered by an energy source to extract raw materials like heavy metals, crude oil, natural gas and coal to make batteries, gasoline and such, or make a device that can harvest solar or wind energy. Every time energy is used to extract energy from material or convert one form of energy into another, energy is both used for the process and lost from the original source. When converting one form of energy to another at least 20% – 40% of the stored energy in the original source is lost. To put it another way, using coal or gas-fired power plants to generate electricity automatically decreases the amount of energy that can be transferred from the gas or coal. Think about how much energy goes up the smoke stack just in heat. Conversion to battery storage loses more. That doesn’t sound very efficient or conservation-minded, does it? Converting more of our other energy sources to drive an ever greater percentage of electric devices makes our system even more inefficient and ultimately less environmentally friendly.

Now lets talk about the hidden costs of electric cars – the batteries and what is used to build them. Most of today’s advanced batteries use lithium as their main reactive ingredient. Lithium is a highly reactive alkali metal that makes it useful across many products, not the least of which are batteries for electric cars. Lithium exists naturally primarily as a constituent of salts found in underground deposits of clay, mineral ore and brine, geothermal water and even seawater. Most lithium is mined and much of it comes from briny lakes, also called salars. Mining lithium carbonate can take up to three years, relying largely on drilling the salar bed, pumping the brine to the surface and allowing the water to evaporate. This takes several months. The stuff is then filtered and moved to another evaporation pond. Repeat as needed. This process uses about 500,000 gallons of water per ton of lithium (I assume our source means lithium carbonate, the precursor to metallic lithium). Put another way easier to visualize, that’s over 34,000 gallons per Tesla Model S electric car, or about the same amount of water an average household uses in six months. Use of that much water has caused lithium mining regions in Chile to lose up to 65% of the area’s water supply. That sounds like a pretty steep price for the locals to pay, as they are now complaining there’s not enough water for agriculture or livestock.

Lithium can also be mined by extracting it from rocks of spodumene, lepidolite and others. The mined coarse gravel must be heated to over 2,000 degrees, then cooled, crushed, roasted and mixed with sulfuric acid and later sodium carbonate to make the final lithium carbonate crystals. It requires even more energy and materials than brining, and so is currently more expensive. All this just to get the raw material to make lithium metal for batteries!

Forming metallic lithium requires an electrolytic mixing bowl of chemicals, where the result is the liberation of toxic chorine gas and molten lithium. It takes about 5.3 lbs. of lithium carbonate to make 1 pound of lithium metal.

Toxic chemicals like hydrochloric acid, sulfuric acid and heavy metals are waste products of these processes, making stream and water table pollution a growing problem. Other battery chemistry is of course being researched, but every process considered at this time has an environmental cost that could yield even larger carbon footprints, once transportation and packaging of battery chemistries are considered. I know two gentlemen in the mining industry and they say lithium is one of the dirtiest metals to mine.

So what about recycling lithium-ion batteries? So far only about 2% of that lithium is being recycled. Now we have them ending up in landfills leaching their toxic chemicals into the soil and water table. And by 2025, lithium demand is expected to quadruple! As usual, humans are jumping on a bandwagon without knowing where it’s headed.

The general public is being led by the nose. They are enamored with the idea of never having to visit the mechanic or gas station again, of plugging their car in at night and just getting up and going. No one tells them about the huge infrastructure costs, the battery farms and the related dirty mining, huge water demands, toxic waste, and manufacturing costs. It’s a fool’s errand to think the electric car will be a total solution. It can be part of a solution, but battery technology and production will have to become much more advanced and cleaner.

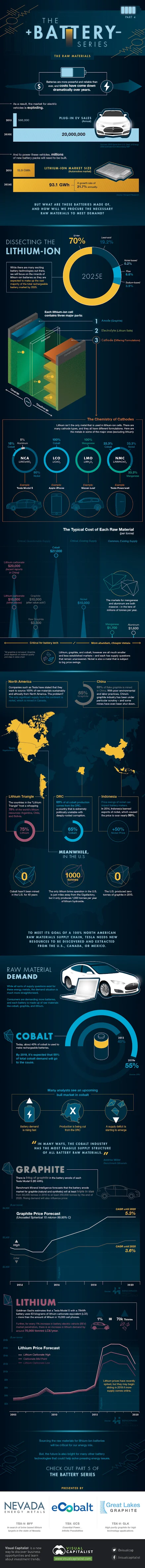

The raw materials needed to produce lithium-ion batteries will also cause new pressures to develop on the geopolitical landscape. China currently dominates the production of the four main minerals required to produce batteries – graphite, nickel, lithium and cobalt. The United States is well behind on all four, essentially with no mining of graphite or cobalt, and only a little lithium. Alliances will be important, as well as strategic investment in domestic mining. There will be a significant strain on the demand to produce more of these essential battery materials in order to keep pace with anticipated electric vehicle demand. That will also put a strain on compliance to environmental concerns.

I’m not saying down with electric cars; they will have a place for many more years. And even though they may well soon become less expensive to buy than gas powered cars, there are other costs of which we need to remain mindful. I think we need to dial back our enthusiasm and get real about the cost, the real carbon footprint and the environmental damage that is always the result of crashing headlong into the void.

There is on-going research to provide options, reduce dependencies on rare materials and improve efficiencies, both in batteries and other bio-sustainable energy sources. For instance, Porsche and ExxonMobil are developing a biofuel that will be carbon neutral when compared to electric cars.

“Synthetic fuel is cleaner and there is no byproduct, and when we start full production we expect a CO2 reduction of 85 percent,” Porsche Vice President of Motorsport Frank Walliser told the U.K. publication Evo. “From a ‘well to wheel’ perspective—and you have to consider the well-to-wheel impact of all vehicles—this will be the same level of CO2 produced in the manufacture and use of an electric vehicle.”

One of eFuel’s big benefits – it can be pumped into a standard gasoline-powered vehicle without needing to make any adjustments to the engine.

As with many exciting moments, we think we have found a silver bullet in battery powered, electric cars. But there is no silver bullet. We are part of the ecosystem; everything is connected and this is no different. No one thing will set us free, but it can certainly go a long ways to enslaving us. Let’s keep our options open.

If you want to get a little nerdy, take a look at the graphic below from a neat little five part series about batteries from the Visual Capitalist.

Sources:

Koop, Fermin. “What’s behind lithium mining? Here’s all you need to know.” ZME Science, January 9, 2020, zmescience.com/science/lithium-mining-098534

Bell, Terence. “An overview of Commercial Lithium Production.” ThoughtCo, August 26, 2020, thoughtco.com/lithium-production-2340123.

Crabtree, George. “The coming electric vehicle transformation.” Science Magazine, October 25, 2019. science.sciencemag.org/content/366/6464/422.full?utm_source=T

Lambert, Fred. “Breakdown of raw materials in Tesla’s batteries and possible bottlenecks.” Electrek.com, November 1, 2016.electrek.com/breakdown-of-raw-materials-in-telsas-batteries-and-possible-bottlenecks/

Desjardins, Jeff. “The Battery Series, Parts 1 to 5.” Visual Capitalist, June 22, 2016. visualcapitalist.com/evolution-of-battery-technology/

Blanco, Sebastian. “Porsche’s Synthetic eFuel Could Make ICE Cars as Clean as EVs (caranddriver.com)“. Car and Driver, February 23, 2021.